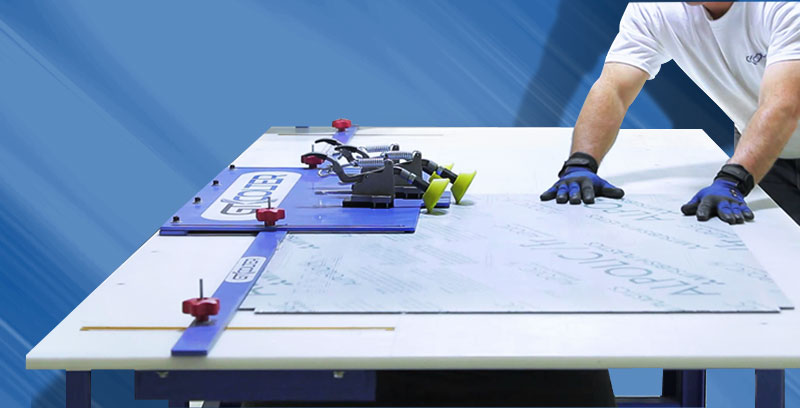

GTColter is the newest, most cost effective aluminum composite grooving machine available on the market. Its welded steel frame and large format work surface allow for easy and fast panel grooving. The GTColter requires minimal power, space and human resources for ACM fabrication. Realize your company’s ability to maximize its profits and…

Scenario

PROJECT

Ford Dealership Showroom Offices

Missouri

PROJECT SUMMARY

99 Panels

3,500 SQFT Material

264' Panel Clip

2,150' Panel Ext.

230' J Clip

PROJECT MATERIAL

ACM Sheet Goods, 50" x 196" (69 SQFT), 3,500 Total SQFT = $19,950

ACM Panel Extrusions (2644') = $3,183

Material Sub Total = $23, 133

PROJECT FABRICATION LABOR

Panelize & Groove ACM Sheets: 15 Hours

Extrusion Assembly: 54 Hours

Total Hours: 72 Hours, $40/Hr

Fabrication Labor Sub Total = $2,880

TOTAL COST = $26, 013

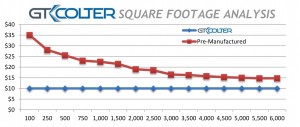

$9.78/SQFT

PURCHASED REGIONAL MANUFACTURER

$17/SQFT = $45,254

DIFFERENCE: $19,241

RETAIL PRICE OF GTCOLTER: $17,950

- REVENUE STREAM

Increase fabrication and profit dollars - PORTABLE

Easily transported for on-site fabrication - RECYCLING

Easily separate waste aluminum and composite materials - SQ FT COST

You control pricing - FLOOR SPACE

Minimal for fabrication & store when not in use - SCHEDULING

Fabricate on your own time line - POWER

110 volt anywhere, anytime - SHIPPING

No crate and freight costs from pre-manufacturing

Click on image to enlarge.